vickers hardness test materials|vickers hardness test diagram : inc The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of . 30 de dez. de 2023 · Quem quiser se inspirar em Homer para tentar a sorte na Mega da Virada, os números apostados pelo personagem foram: 01, 06, 17, 22, 24 e 35. O .

{plog:ftitle_list}

Resultado da Central SESC-SC. 0800 645 5454. [email protected]. Por favor informe o CPF ou matrícula.

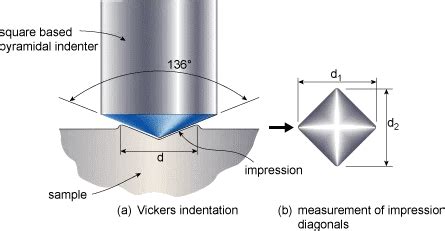

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .Vickers hardness is defined as the ratio of the force F acting on the diamond indenter (regular four-sided pyramid shape) and the surface A of the indentation (on the surface of the object .

The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist deformation .

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .

This test is known for its wide applicability, from soft metals like lead to the hardest, such as tempered steel & ceramics. How the Vickers Test Works. It involves pressing a small, . Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. Significance and Use. 4.1 Vickers and Knoop hardness tests have been found to .The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials with low hardness. Small test loads < 0.2 kgf that create small indents on the .

The Vickers hardness test. Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load.Vickers Hardness Test. The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the indentation is . Hardness testing is measuring a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. Learn more about it here. . ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell .1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .Engineering Metals and Materials Table of Contents. Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness .

In material science, the Vickers hardness test stands out as an exceptionally reliable & flexible method for assessing the hardness of a diverse array of materials. This technique is crucial not only in aerospace but also in manufacturing small, precision-engineered components, offering precise measurements across different material types. As .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .

Digital Thickness Meter store

The load value on the unit indentation area is the Vickers hardness of the metal material. . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can .Metallic materials — Vickers hardness test — Part 1: Test method. Edition 4 2018-01. Withdrawn. ISO 6507-1:2018. 64065. ISO 6507-1:2018 Metallic materials — Vickers hardness test Part 1: Test method. Withdrawn (Edition 4, 2018) New version available: ISO 4545-1:2023, ISO 6507-1:2023. Abstract.

This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F Low-force Vickers hardness test < 49,03 HV 0,2 to < HV 5 0.009 807 ≤ F < 1.961 N - Designation: HV 0.001 to

The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test. The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. The .Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin coatings or materials with a small indentation requirement. Knoop belongs to the optical methods. Knoop HardnessVickers hardness testing is frequently used, but Rockwell hardness values may be needed for specific client requirements or material certifications. 3. Metallurgy and Material Science: Researchers working on developing new materials, especially alloys, often need to convert between hardness scales to compare the performance of different .

Applications of Vickers Hardness Testing: Material Characterization: Vickers hardness testing is commonly used to determine the hardness of various materials, including metals, ceramics, and polymers.This information is crucial for understanding material properties, such as wear resistance, toughness, and strength.

vickers hardness testing procedure

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the . The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to the material’s surface, creating a square-shaped indentation. After the load is removed, the diagonals of the indentation are measured .The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the opposite faces at the vertex, which is pressed into the surface of the test piece using a prescribed force, F. The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s.

Digital Plastic and Rubber Thickness Meter store

Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials. When choosing materials for engineering purposes, this information is helpful.

At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). 1.ISO 6507-1 Metallic Materials—Vickers hardness Test— Part 1: Test Method 3.2.3 macroindention hardness test, n—a hardness test using ISO/IEC 17011 Conformity Assessment—General Require- test forces normally higher than 9.807 N (1 kgf). Macroinden- ments for Accreditation Bodies Accrediting Conformity tation tests include Vickers .

Pipe wall Thickness Meter store

Dumbbell Sample Cutter store

LCD Melt Flow Indexer store

webMinistério Zoe. Letras. Álbuns. Fotos. Relacionados. Popularidade. Até Que o Senhor Venha. Ministério Zoe. Estrada da Fé. Oh, se você rasgar o céu. Apenas mais uma vez. .

vickers hardness test materials|vickers hardness test diagram